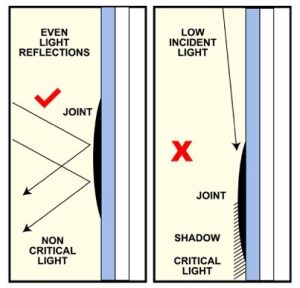

Glancing light is the light that shines obliquely across the surface of a wall or ceiling that magnifies surface irregularities and can make a high quality surface finish look imperfect.

Installers and finishers aim to achieve the appearance of a flat and even surface for both walls and ceilings which at times can be impossible due to inevitable surface variation which may be caused by:-

- Differences in the framing / joints

- The hand-finished nature of a plasterboard wall or ceiling

- Subtle differences between the textures of plasterboard and the jointing compounds

Under the majority of lighting conditions a plasterboard surface will appear flat.

In critical lighting conditions, an effect referred to as ‘glancing light’, will highlight any surface variations.

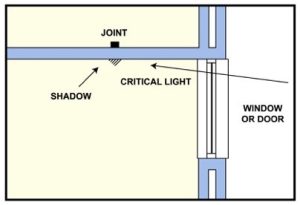

Critical Light is a phenomenon that occurs when sunlight or another source of light strikes a surface at a 15 degree angle or less. At this angle any irregularity on the surface can cast a shadow and make the surface look uneven. Depending on the source of light, this may be highlighted at a specific time of day and for a limited period of time, and does not affect the performance of the system, but merely the aesthetic for the period of time that the light casts this shadow or reflection.

The Glancing Light phenomenon is accentuated under the following conditions:-

- Floor to ceiling windows

- Windows directly adjacent to walls

- Unshaded light bulbs

- Ceiling mounted fluorescent lights

- Wall lights and downlights close to walls

- Windows at the end of long corridors

- Brightly lit rooms

- Lights installed just below a raked ceilings

- Reflections of light from water features

- Gloss or sheen paint finishes

As with acoustics in buildings, the best time to reduce the effects of glancing light is for it to be considered during the design stage.

With large expanses of glass being a popular design feature in modern buildings, glancing light has become even more important to factor in at design stage.

The effects of natural and artificial light and how the light will fall on the walls and ceilings throughout the day are important, but especially the mornings and evenings when the sun is lower in the sky and casts elongated shadows that can magnify any surface variations in walls and ceilings.

Considerations at design stage:-

- Building aspect

- Placement of Windows

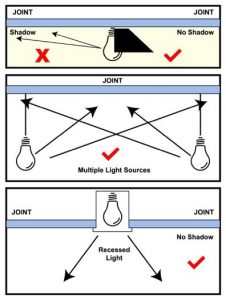

- Ceiling and wall joints need to run in the direction of the light source e.g. at right angles to the windows or large openings

- Avoid butt joints wherever possible

- External reflective surfaces including pools, neighbouring buildings and water features that can reflect light into the space

- Lighting types and positioning

- Paint Finishes

Where glancing light is deemed to be a concern it is recommended that after finishing the joints, that the entire surface is skimmed to conceal imperfections in the joint work.

The use of external shading or vertical louvres can be useful to reduce the effects of glancing light, as well as the use of curtains or interior blinds.

Lighting Considerations

Wall mounted up or down lights and high output lighting will accentuate imperfections.

The whiter lighting will also create a stronger contrast to the shadow and magnify the perceived imperfection.

A central light in a ceiling, especially unshaded will cast angled light in all directions.

The best lighting choices make use of diffused light which minimises the appearance of surface variations including recessed ceiling lights such as downlights and recessed fluorescent lights, ceiling mounted pendant lights, shaded light fittings and the use of more lights of lower intensity.

Paint Considerations

A plasterboard surface with two different materials, the plasterboard and the jointing compound each have different textures and porosity. If the plasterboard surface has not been skimmed completely concealing the joints and unifying the surface texture, then it is important to apply a plasterboard primer and sealer for painting preparation.

It is ideal to use a roller application and two coats of a water based paint.

A matt paint finish will provide the highest level of light diffusion, and gloss finishes including satin and semi-gloss can accentuate even minor variations in the surface finish.

The choice of colour will also have an effect, with light colours being most effective to diffuse light.

If dark colours will be used, then surface finish becomes even more important.

In summary plasterboard surfaces are never perfectly flat even with the most careful professional finish. These minor surface variations while unnoticeable under normal light conditions can be highlighted by a combination of glancing light and sheen or gloss paint finishes.

Consider these factors ideally during design stages, or during installation and finishing so additional finishing measures can be applied to reduce the effects of glancing light. As a contractor this is a great value add you can contribute by picking up and noting any potential problems that might be caused by glancing light. If noticed early enough then lighting and paint selections can be amended if need be to address any glancing light issues before the project is handed over.